Description | |

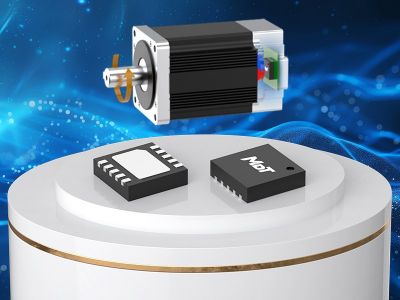

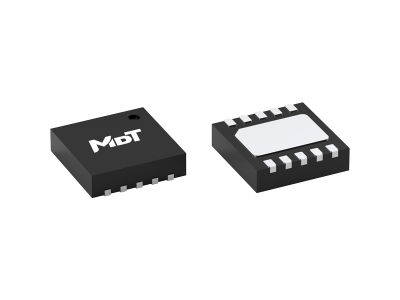

The TMR3111 is a contactless, high-precision, and high-speed magnetic rotary encoder sensor, which integrated with tunneling magnetoresistance (TMR) sensors and CMOS digital signal processing circuitry. The TMR3111 senses the single pole-pair magnet rotation above the chip by TMR sensors, collects the rotating magnetic field signal, transmits it to the digital processing unit, and calculates the rotation angle. The TMR3111 supports 3-wire and 4-wire SPI working modes, allowing the client MCU to read 23-bit absolute position information through the SPI protocol. Additionally, the chip also provides a 12-bit resolution PWM output interface, with the PWM frequency configurable in four levels according to customer requirements. It is able to output A/B phase programmable incremental position signal with 1 to 4096 pulse and programmable zero-point (Z phase) signal. TMR3111 also provides inverted UVW output, analog and PWM signals, with rotational speed up to 40,000 RPM. The TMR3111 can self-calibrate to compensate non-linearities caused by imperfect installation. |  DFN10L (3mm × 3mm × 0.75mm) DFN10L (3mm × 3mm × 0.75mm) |

Features and Benefits | |

Tunneling magnetoresistance (TMR) technology Tunneling magnetoresistance (TMR) technology |  Supply voltage: 3 V to 5 V Supply voltage: 3 V to 5 V |

Available in SPI, ABZ and PWM interfaces Available in SPI, ABZ and PWM interfaces |  Supply current: 10 mA (typical) Supply current: 10 mA (typical) |

Programmable A/B/Z interpolation factors from ×1 to ×4096 Programmable A/B/Z interpolation factors from ×1 to ×4096 |  Speeds up to 40,000 RPM Speeds up to 40,000 RPM |

Integrated automatic gain calibration function Integrated automatic gain calibration function |  Angular repeatability < ±0.05° Angular repeatability < ±0.05° |

Integrated EEPROM rewritable over 1000 cycles Integrated EEPROM rewritable over 1000 cycles |  On and off axis measurements On and off axis measurements |

Supports 0° to 360° absolute angle detection Supports 0° to 360° absolute angle detection |  Angular output delay < 2 μs Angular output delay < 2 μs |

RoHS and REACH compliant RoHS and REACH compliant | |

Applications | |

Contactless angular position measurement Contactless angular position measurement |  Brushless motor position sensing Brushless motor position sensing |

Rotary speed sensing Rotary speed sensing |  Close loop stepper system Close loop stepper system |

Servo encoder Servo encoder | |

- Home

-

Products

- Sensor ICs

- TMR Switch Sensors

- TMR Angle Sensors

- TMR Linear Sensors

- TMR Gear Speed Sensors

- AMR Switch Sensors

- AMR Angle Sensors

- AMR Linear Sensors

- AMR Magnetic Scale Sensors

- Sensor Modules

- TMR Magnetic Image Sensors

- TMR Current Sensors

- TMR Geartooth Encoders

- AGV Magnetic Guide Sensors

- TMR Low Noise Linear Sensor

- TMR Linear Displacement Sensors

- TMR Flow Sensors

- USB Magnetometer

- Fabrication Service

- Demonstration Boards

- About MDT

- Technology

- Shop

- Contact us